In response to the rapid development of the pet food market and consumers' increasing attention to the quality and safety of pet food, our packaging machine manufacturer has proposed a set of professional Pet food packing manufacturing plant turnkey project. This solution aims to provide one-stop packaging services for pet food companies through innovative design concepts, efficient production processes, environmentally friendly material selection and intelligent logistics systems, helping them enhance their brand image and expand market share.

Package

GuanJia is a world leader in packaging dry bulk materials into bags using a variety of industrial packaging equipment. Each dry bulk packaging machine has a special focus on the industrial bagging market. GuanJia specializes in the pet food industry and strives to provide customers in these fields with the latest technology and expertise. We are able to offer valve bag filling machines, bulk bag filling machines, tube fill seal bagging machines and open top bagging machines.

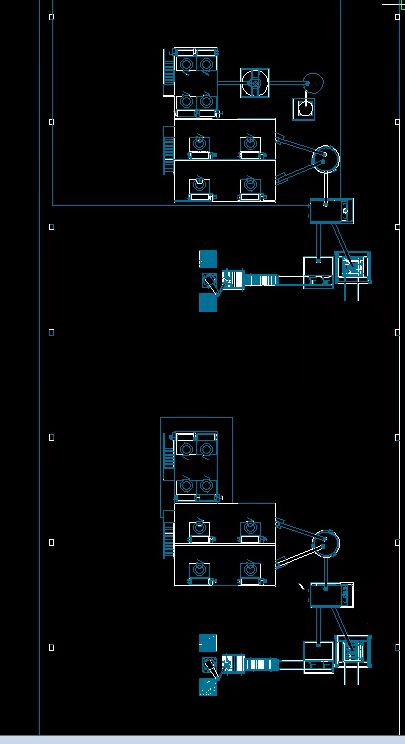

Packaging machine selection:

Granular and flake materials can be packed using the following methods:

- Granule bucketless filling machine is suitable for output of 200 to 300 bags per hour and used for 10KG to 50KG packaging bags.

- Granule single bucket filling machine is suitable for output of 300 to 400 bags per hour and used for 5KG to 50KG packaging bags.

- Granule double bucket filling machine is suitable for an hourly output of 400 to 700 bags, and is used for 5KG to 50KG packaging bags.

Palletizing

Palletizing occupies a vital position in the field of packaging and transportation. It greatly improves transportation efficiency by stacking pet food bags and other containers neatly and orderly on pallets. Companies involved in almost every industry use palletizing technology to ensure that bags are stacked and secured in a consistent and stable manner, thereby significantly reducing the risk of damage that may occur during transportation. This not only helps reduce waste and prevent product loss, but also helps pet food manufacturers save costs. By using automatic palletizing systems produced by GuanJia, pet food manufacturers can also enjoy greater flexibility in their production processes. These systems can be programmed to handle bags of various sizes and shapes, making them suitable for a variety of products and applications.

End of production line

After the bagging and palletizing process is complete, the final step before storage and shipping is to protect your pallets. For this purpose, we use an efficient end-of-line stretch hood system. This method ensures optimal stability of the pallet during transport, while also effectively protecting the bag from moisture and dust, ensuring it is protected.