As a country with rich agricultural resources, Saudi Arabia has corn as one of its main crops and has extremely high economic value. Taking into account the cultural background and consumer needs of the Saudi market, we designed a comprehensive and practical product packaging solution for local corn producers:

Production line planning

1. Raw material reception and storage: First, a dedicated area needs to be set up to receive and store corn raw materials. This area should have sufficient storage capacity to ensure continuous operation of the production line.

2. Pretreatment: Before packaging, corn may require some pretreatment, such as cleaning, drying, etc. This ensures product quality and hygiene.

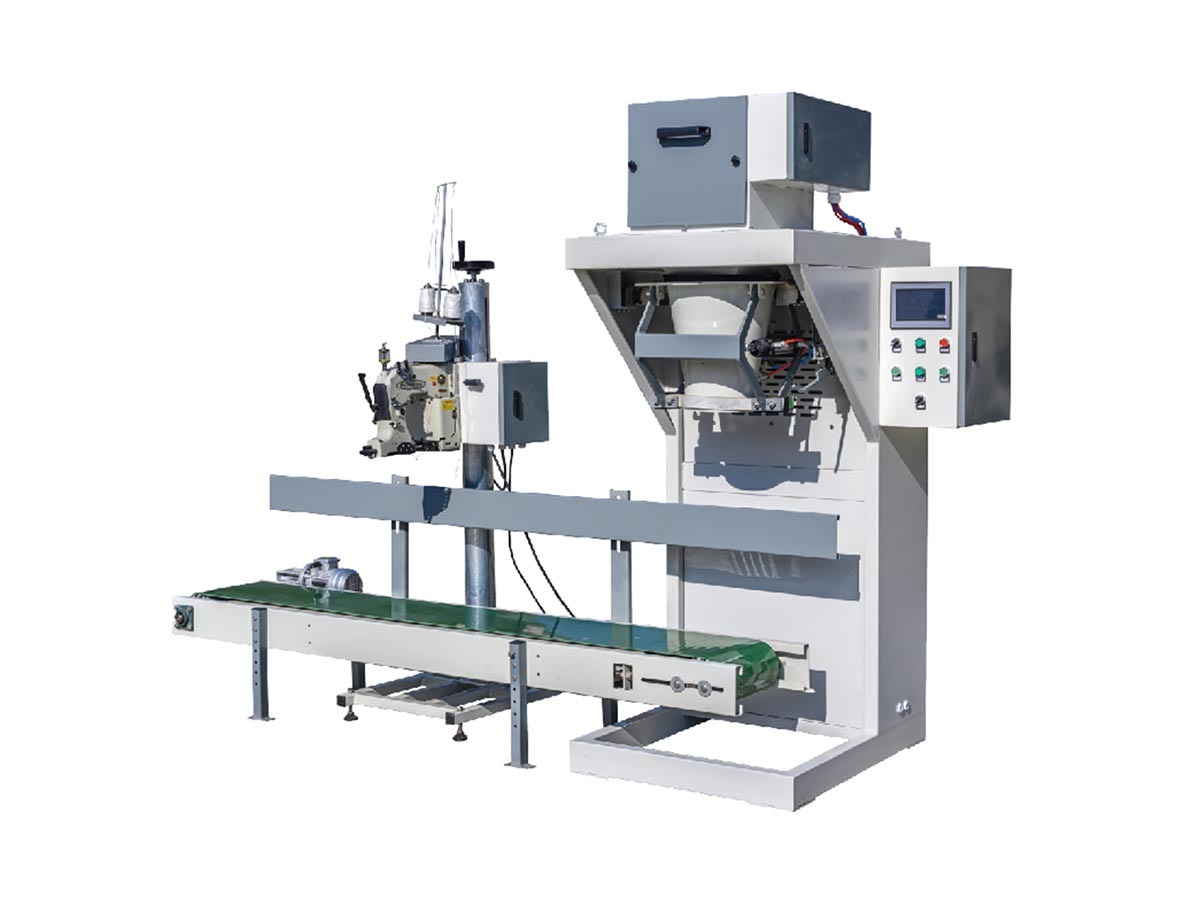

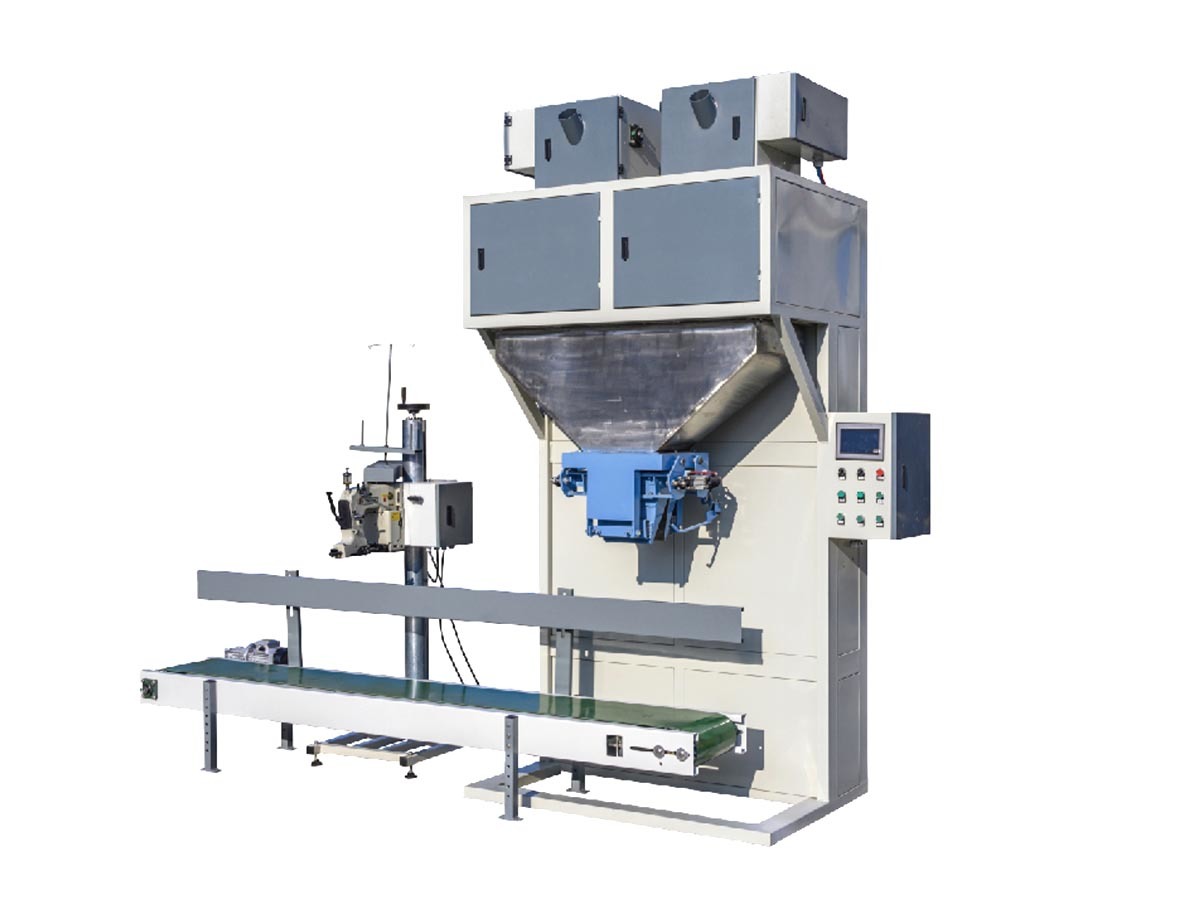

3. Measuring and filling: Use automatic measuring and filling equipment to fill corn into packaging bags according to the preset weight or volume. This improves productivity and accuracy.

4. Sealing and packaging: After filling is completed, the packaging bags need to be sealed and packed into units suitable for transportation. The seal should be strong and beautiful to prevent the product from leaking during transportation.

5. Finished product storage and delivery: Finally, the packaged corn is stored in the finished product warehouse and awaits delivery. When shipping, packing and marking should be carried out according to the customer's requirements.

Device Selection

Choose efficient and stable packaging and sealing equipment to ensure packaging quality. The equipment should have automatic adjustment function to adapt to packaging bags of different specifications and materials. Since corn is a granular material that is easy to package, we recommend a pellet packing machine, which can achieve a maximum packaging speed of 700 packages per hour. In order to improve production efficiency, you can consider introducing automated conveying and palletizing, such as conveyor belts, palletizers, etc. These devices can reduce the workload of manual handling and reduce production costs.