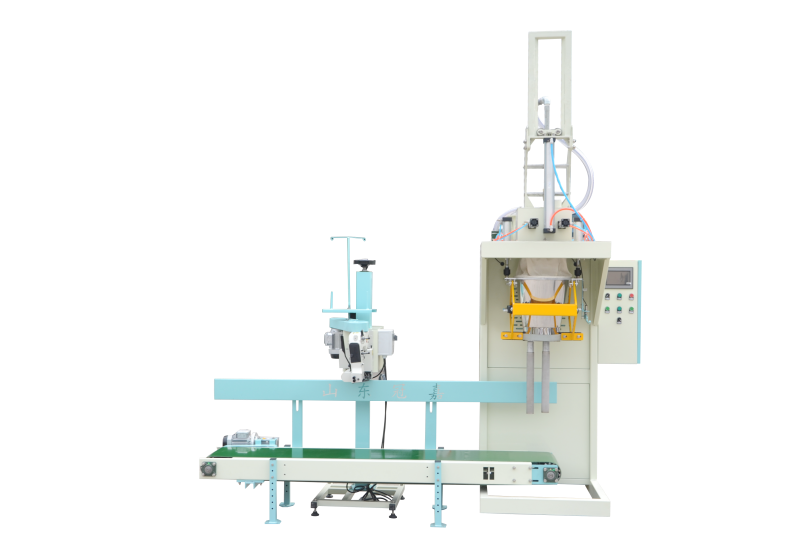

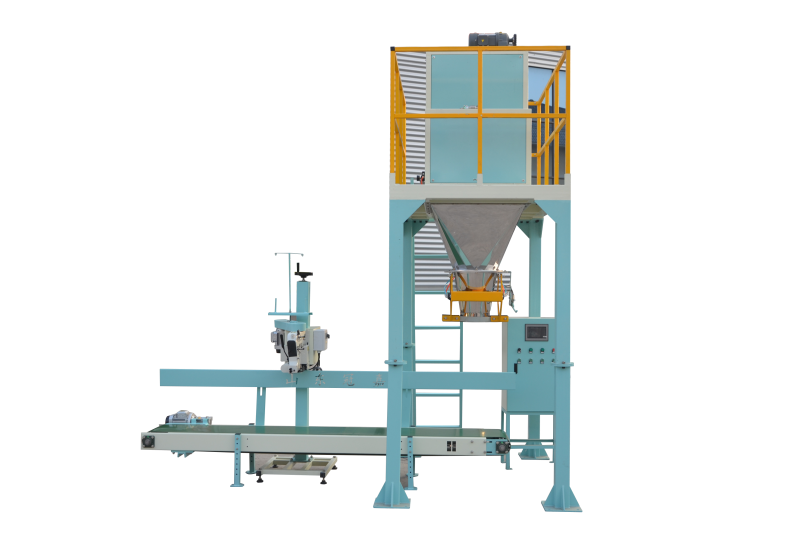

The common weighing methods for quantitative packaging scales include single sensor, double sensor, three sensor, and four sensor forms. Among them, single sensors are generally used for simple results without bucket scales and small packaging scales, double sensors are used for ordinary packaging with bucket scales, three sensors are used for packaging with high accuracy requirements, and four sensors are used for weighing heavy packaging, such as ton package

The number of sensors determines the design of the packaging scale mechanism, which has a significant impact on the speed/accuracy and other performance of the packaging scale. The design of the three sensor structure is based on the principle of using three points to determine a plane, so that the measuring bucket is stable and free from lateral shear and torsion forces, packaging accuracy and stability do not swing, and is not affected by mechanical manufacturing errors, such as welding deformation and assembly errors. The instrument packaging controller receives stable net weight data signals, greatly reducing the time for calculating data signals and further improving productivity compared to single/dual sensor structures. The use of nitrogen filled metal corrugated tube weighing sensors and their weighing calculation technology can completely solve the problem of angle difference. The disadvantage is the increase in manufacturing costs, but it is still a worthwhile choice for packaging scale measurement