Debugging coffee powder packing machine is a very important job because it is related to the quality, efficiency and safety of the product.

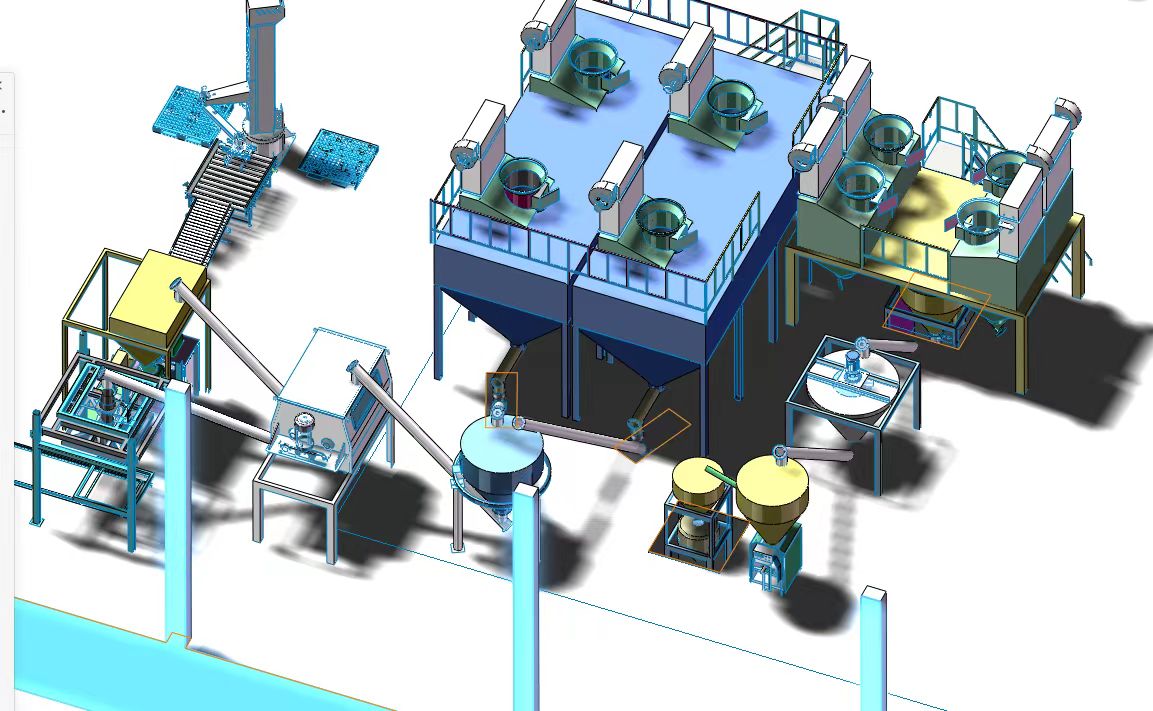

In order to ensure the normal operation of the coffee powder packing machine, we need to first check whether each component is installed correctly, whether the lines are connected properly, and whether the air pressure is normal. This process is very tedious and requires careful observation of every part to ensure the safety and reliability of the machine. Next, we need to carry out mechanical debugging. This step is mainly for debugging the mechanical part of the machine, including bearing lubrication, gear matching, chain tensioning, etc. This step tests the technical level and patience. It requires careful observation of every detail of the machine's operation to ensure the smooth operation of the machine. After the mechanical debugging is completed, we need to conduct electrical debugging. The electronic control system of the packaging machine is very complex, so we need to check the wiring table of each circuit, the wiring status of the controller, etc. very carefully. During the electrical debugging process, we need to pay special attention to safety issues to avoid accidents such as electric shock.

Finally, we need to debug the coffee powder packing machine function. This step is the core step in the entire debugging process. It requires various experiments to test whether the various functions of the machine are normal. For example, we need to test the automatic feeding function, automatic running function, automatic packaging function, etc. of the coffee powder packing machine. If you find a functional problem during the debugging process, you need to go back and conduct more detailed debugging.

The debugging of coffee powder packing machine is a very important task, which requires continuous discovery and processing of problems. Only through continuous exploration can we make the coffee powder packing machine run more perfectly.