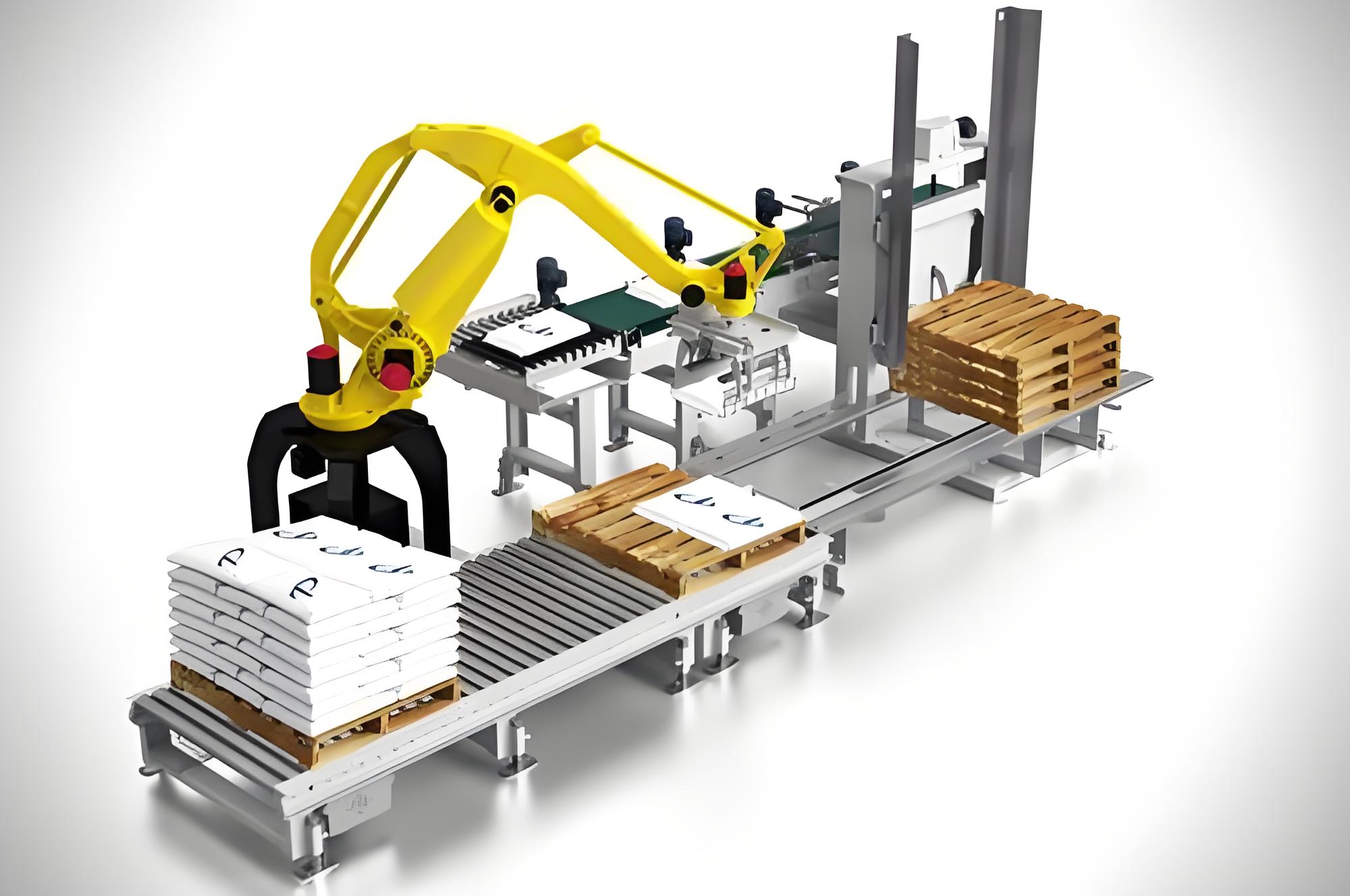

The palletizing robot solution is a comprehensive system designed to achieve an automated, efficient and precise palletizing process. The following is a detailed description of the palletizing robot solution:

System composition and working principle

The palletizing robot solution mainly includes the robot body, control system, sensor system and actuators such as grippers or suction cups. Its working principle is as follows:

- Perceiving objects: The robot perceives the surrounding environment and the position, shape and size of the objects to be processed in real time through visual sensors, laser sensors, etc.

- Planning paths: According to the perceived object information, the control system uses algorithms to plan paths to ensure that the robot can move efficiently during the palletizing process and avoid collisions or repeated movements.

- Grasping objects: The robot activates actuators such as grippers or suction cups to accurately grasp the objects to be processed. The design of the grippers or suction cups must have sufficient strength and flexibility to ensure that the grasping process is stable and does not cause damage to the objects.

- Moving and stacking: The robot moves the grasped objects to the specified location and stacks them according to the preset rules. During the stacking process, the robot needs to accurately control the position and direction of the objects to ensure the stability and correctness of the stacking.

- Detection and adjustment: The robot is equipped with sensors such as pressure sensors, etc., which are used to detect problems in the stacking process, such as object position offset, unstable stacking, etc., so as to make timely adjustments.

Application advantages

- Improve production efficiency: The palletizing robot can work continuously and stably, greatly improve production efficiency and reduce labor costs.

- Improve palletizing quality: The robot has high palletizing accuracy, which can ensure the stability and safety of stacking, reduce cargo damage and human errors.

- Strong adaptability: The palletizing robot can adapt to objects of different shapes, sizes and weights, and has strong versatility and flexibility.

Solution customization and optimization

Customization according to customer needs: Customize suitable palletizing robot solutions according to factors such as the customer's production environment, object characteristics and palletizing requirements.

Optimize path planning algorithm: Improve the robot's movement efficiency and stability by continuously studying and improving the path planning algorithm.

Improve sensor performance: Use advanced sensor technology to improve the robot's perception ability and accuracy and reduce the misjudgment rate.

Implementation and maintenance

- Installation and debugging: Ensure that the robot is correctly installed and connected to the control system, sensor system, etc., and perform necessary debugging and testing.

- Operator training: Provide necessary training to operators so that they can master the basic operation and maintenance knowledge of the robot.

- Regular maintenance and care: Regularly maintain and care for the robot to ensure its stable performance, safety and reliability.