What one must know when choosing a person to operate a packaging scale.

The development history of operating packaging scales by one person:

When it comes to operating a packaging scale alone, it's not really something new. Why do you say that? Don't underestimate human intelligence and technology. In fact, there have been packaging scales that are more advanced than just one person operating them now. We don't know when the first one appeared in the world. About 20 years ago, I witnessed a fully automatic packaging scale that automatically sets bags and sews without human operation. Unfortunately, it is produced abroad and the price is very expensive, which ordinary users cannot afford.

The application of new technologies usually has a significant guiding effect on the market, and we were all quite impressed at that time, so we made up our minds to vigorously research and develop in this direction. Many manufacturers in the industry may have the same idea as us, but the investment and manpower required to develop this model are very large. We have been continuously developing and testing it for about 3 to 4 years. Our R&D approach has always been focused on modularity, facilitating customer configuration of different functional modules and achieving compatibility with products from other manufacturers. From automatic bagging to automatic sewing thread, each module has several solutions that consider stability, cost, and maintenance in the later stage. Each solution requires making a prototype for physical testing, summarizing experience, and improving, so it was very difficult at that time. Of course, these tasks are all meaningful, as technological accumulation and experience are also intangible assets. During this period, we also encountered many fully automatic models manufactured by domestic manufacturers, which initially had poor results and even ended up being unusable. Our goal at that time was very clear: to use our own technology to minimize investment for customers, rather than looking at the high prices of foreign machines and sighing. It's a bit far fetched, but when it comes to that period of time, I feel a bit excited.

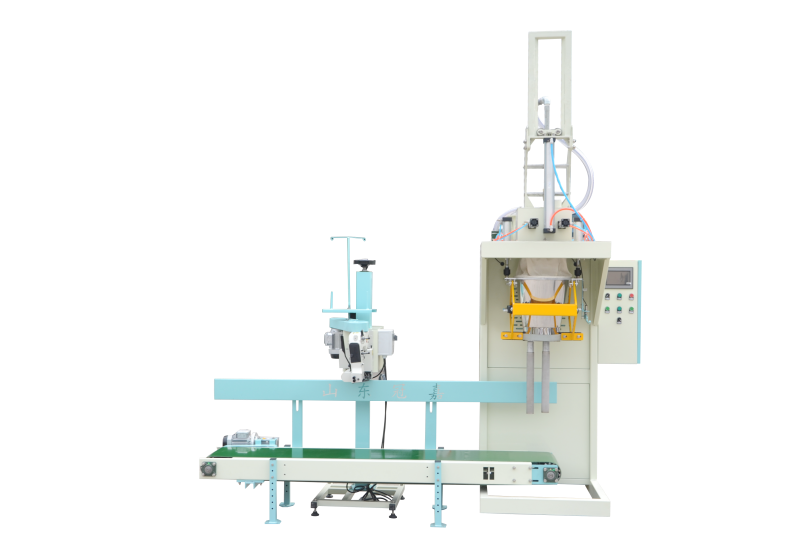

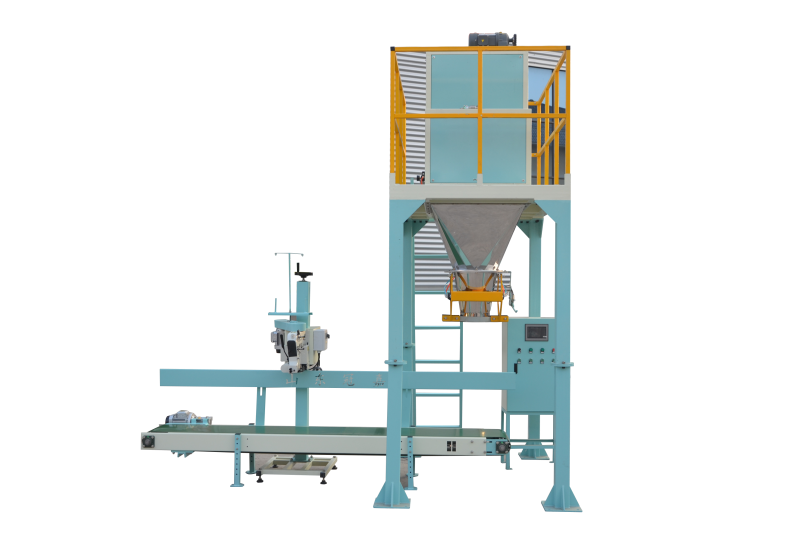

There are also many powerful packaging scale manufacturers in China, among which there are also those that attach great importance to research and development. After so many years of effort, foreign technological barriers are gradually being broken down, and mature fully automatic models in China have also emerged. Although the price is several times cheaper than before, it is still relatively high compared to some industry customers. For example, grain filling, in recent years, the competition in the grain industry has increased, and human costs have sharply increased. The grain industry urgently needs to reduce expenses. Previously, we designed and installed fully automatic models for customers in the seed packaging industry, and the results were quite satisfactory. However, the price of the machines was still too high compared to the grain packaging scales at that time, until a customer who made grain complained that it was too difficult to find people to work with, and that they could not usually raise so many people in the field. When people were needed, they could not be found at that time, but they could not invest too much in the equipment. At that time, we thought to ourselves: Why can't we settle for second place? Although the fully automatic model requires two fewer people, the equipment investment is high. However, if we only consider saving one person, the equipment investment will be greatly reduced. Later, after design and development, the functional modules in the fully automatic model were actually tailored and simplified according to the characteristics of grain packaging, ensuring the stability of use and maximizing cost savings. This product is a grain packaging scale operated by one person.

Our first generation of one person operating the grain packaging scale did indeed have many flaws at that time, including structural design and software control. The control scheme at that time was separate, equivalent to a separate set of control for the packaging scale and a set of control for automatic sewing. The two systems were inherited through data interface connection. The disadvantage of this method is that it cannot be deeply controlled and the setting operation steps are complex. Many parameters cannot be set through the touch screen of the packaging scale. Of course, users are not concerned about professional skills, but rather about the ease of operation. We were also aware of this issue from the beginning, so we specifically developed an integrated packaging seam control system later on.

The second generation model has already adopted this specialized control system, and the customer's response is very good, after all, there has been a qualitative leap in the operating experience.

We have summarized the feedback from customers and the shortcomings of the latest third-generation models, and carried out a major reform in the mechanical structure design.

Nowadays, there are gradually more manufacturers on the market who can operate grain packaging scales by one person. In terms of appearance, they are all similar. Some manufacturers also have very beautiful workmanship, while others have relatively rough workmanship. When choosing a machine, we should definitely prioritize choosing a machine with good appearance. However, it is a big mistake to think that selecting a machine based solely on appearance is enough. Nowadays, mechanical processing technology is generally advanced, and laser and CNC machining are basically popular. Therefore, the difference in machine workmanship is only about appearance. The actual performance still needs to be carefully selected. Just a few simple points, such as supporting the bag, although it is just an inconspicuous action, it has a significant impact on the entire sewing process. For example, threading, many manufacturers have this problem. Sewing machines are very inconvenient to thread, and after threading, the entire sewing mechanism needs to be adjusted, which is very troublesome. For example, is it convenient to adjust the sewing machine and conveyor to the optimal working state. There are also bag traction, whether it is belt type or chain type, and the adjustment parameters of the guide bag, etc. In short, operating a grain packaging scale by one person is relatively new, and there are significant differences in the technology of manufacturers. If you can't buy it well, take medicine. Don't trust the salesperson's boasting too much, because many salespeople themselves don't understand what they are talking about. So when choosing, you need to carefully discern.

By the way, many people have doubts about the issue of failure rate. They say that people say that packaging scales operated by one person often have problems. In fact, this kind of thing is not difficult to understand. The components and system hardware themselves are not prone to problems, and the cause of problems is still due to machine design problems or defects. Many potential problems are the reasons for difficulties in subsequent use.