The difference between a bucket scale and a bucketless scale

The main difference between "bucket scale" and "non bucket scale" is that one has a bucket and the other is non bucket, which is easy to understand. But where is this dou from? This issue often leads to misunderstandings among people who are not familiar with packaging scales.

Many people mistakenly believe that there is a hopper, and when looking at a packaging scale, there is a hopper at the top of the equipment, also known as a silo. In fact, this bucket is not what we call a bucket with or without a bucket scale. This hopper is a must-have for quantitative packaging scales, whether it is a hopper scale or a non hopper scale.

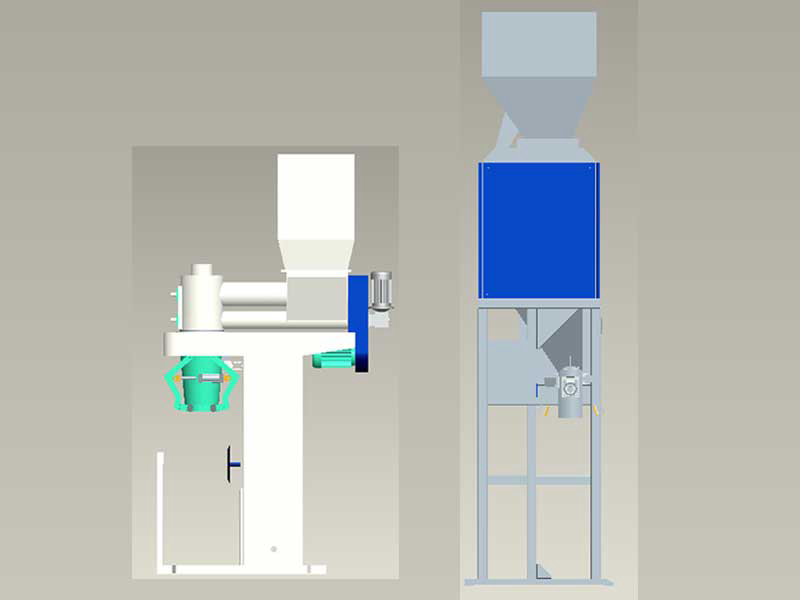

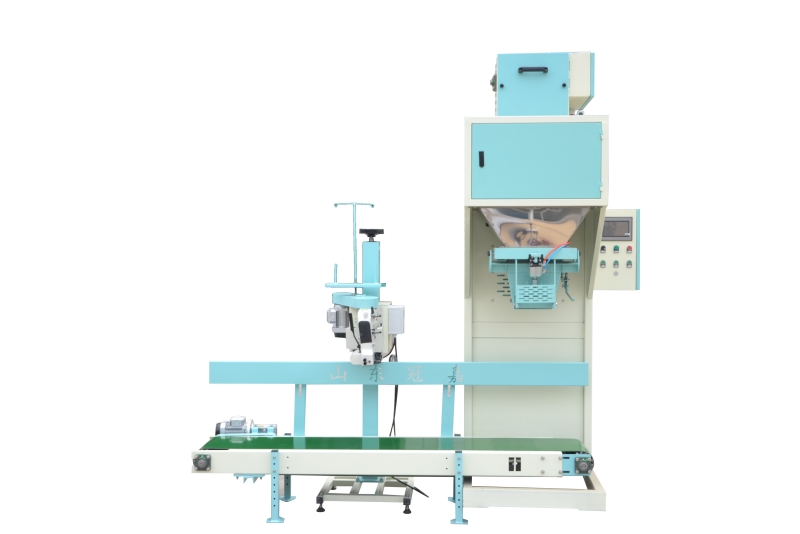

Next, let's talk about the real "bucket": the real "bucket" is a "measuring bucket", also known as a "weighing bucket". The essence of a bucket scale is that the material weighing and carrying method is a "hopper type" gravity automatic loading scale (refer to GBT 26389-2011 Scale Product Model Preparation Method). This bucket is essentially a scale, shaped like a hopper. The entire bucket is supported and suspended by weighing sensors, and there is a discharge door below. After the measurement is completed, the discharge door opens and the material flows into the bag, completing a weighing process. So what does "no bucket scale" mean? A non bucket scale means that there is no "measuring bucket", and the entire measurement is completed inside the packaging bag. In fact, the "measuring bucket" is omitted, and the packaging bag is placed on a bag clamping device. This bag clamping device is actually supported and suspended by a weighing sensor, and then clamped on the bag, forming a working mode of directly feeding and measuring into the bag.

So the working conditions of the materials in the hopper scale are: silo - feeding mechanism - measuring hopper (weighing) - bagging - sealing; And the non bucket scale is: silo - feeding mechanism - bagging (weighing) - sealing. So although these two packaging scales are only one word wrong, their working modes are completely different, and the difference is also very significant.

In summary, "with a bucket scale" and "without a bucket scale" can be divided into the following points:

Different scales have different body structures, resulting in different body heights. A scale with a bucket is often about 1 meter higher than a scale without a bucket, making it more complex and costly.

The speed is different, with a bucket scale having a faster speed, and with a bucket scale weighing not affected by bagging, it automatically cycles; The non bucket scale requires a bag to start weighing, and the speed is slower. The general accuracy is inferior to that with a bucket scale.

Adapting to different materials, in general, granular materials are preferred to have a bucket scale, while powder materials can be selected with or without a bucket scale. The specific plan will be determined based on the specific situation.

Double scales with a bucket scale usually have one bag opening, while double scales without a bucket scale usually have two bag openings.

The above is the meaning and difference between non bucket scale and bucket scale.