Alona Grelia is a seed producer from the Philippines, mainly producing high-quality crop seeds such as corn, wheat, soybeans, etc. However, traditional encapsulation machine cannot meet its special needs. In order to further drive the company's production capacity, save labor and production costs, Alona Alegria, the manufacturer, hopes to find a packaging machinery company that can provide customized services to improve packaging efficiency and seed quality. So they contacted GuanJia to develop a packaging plan suitable for our company.

Customized service plan

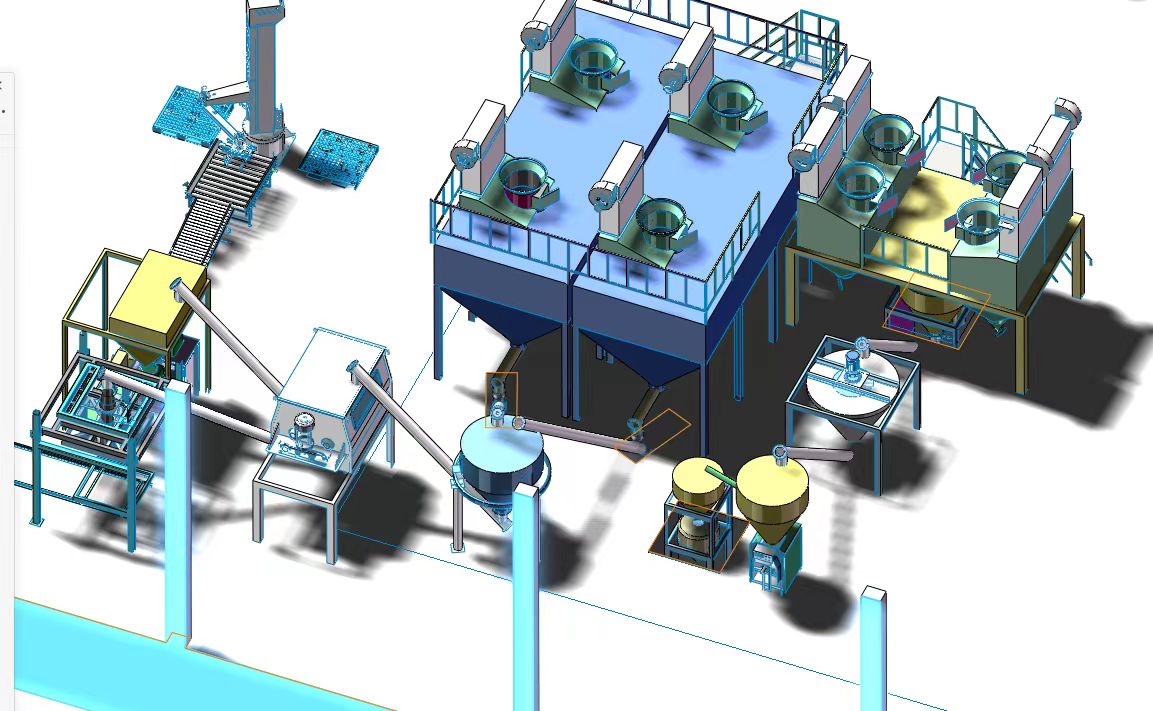

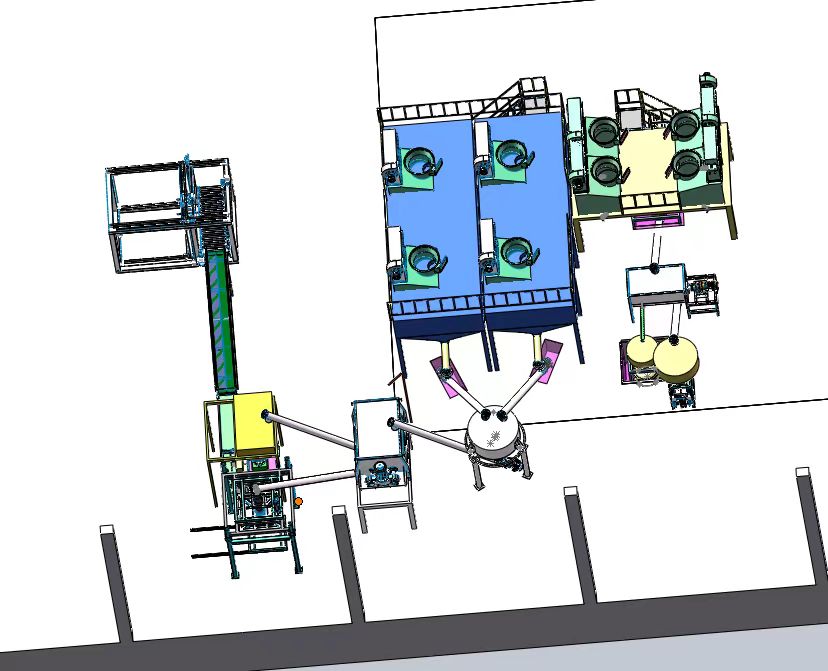

After gaining a deep understanding of the production process and requirements of seed producers, we suggest that Alona Alegria choose a encapsulation machine with high automation, speed, and packaging accuracy. Therefore, our recommended solution includes a granule encapsulation machine and a palletizing machine, as well as necessary connections between conveyor belts and automated transportation systems, for transporting pallets directly to the warehouse, which greatly saves labor. At the same time, Alona Alegria company requires the weight of each bag of fertilizer to be 35kg/bag. The weighing range of GuanJia's granule packaging scale is 10kg-50kg, and the maximum weighing speed can reach 400-700kg/h. This encapsulation machine largely meets the requirements of our partners. The manufacturer is very satisfied with the customized service provided by GuanJia Packaging Machinery Company, believing that it not only meets their special needs, but also improves production efficiency and seed quality. They expressed willingness to continue cooperating with packaging machinery companies and recommended it to other peers.

Implementation effect

Through the implementation of customized services, the production efficiency and seed quality of seed producers have been significantly improved. Specifically:

1. Improved production efficiency: The precise measurement and automation functions of the new encapsulation machine greatly improve the speed of seed packaging, while reducing manual intervention and errors.

2. Cost reduction: The environmentally friendly and energy-saving design significantly reduces production costs, bringing higher economic benefits to seed producers.