Detailed diagram of the working principle and process of automatic quantitative packaging scale

What is the working principle of an automatic quantitative packaging scale? To understand this question, the first thing to know is what an automatic quantitative packaging scale is? As the name suggests, it is capable of automatic weighing, which means it has the function of a scale, and then it can automatically add materials to the scale and accurately achieve the required weight. Then it is the function of packaging, which can be bagged and then sealed. This is the basic function of packaging scales. Its working principle is actually to complete this series of functions and then loop continuously.

Next, we will provide a detailed explanation of the principle behind completing the weighing and packaging process separately for the packaging scale:

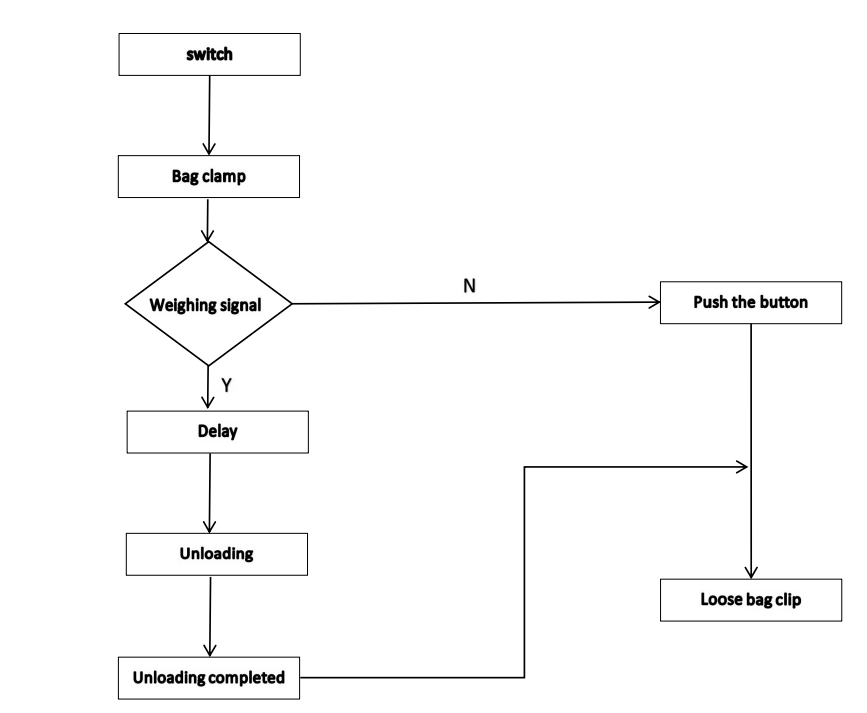

The above picture shows the bagging and material discharge process of a bucket scale: manually bagging and turning the switch, the bag is clamped. If the weighing bucket has materials weighed and a weighing completion signal has been issued (the completion indicator light is on), the material discharge door of the measuring bucket will open, and the materials will be discharged into the bag. After the discharge delay, the material discharge door of the measuring bucket will close. After a delay (before loosening the bag), the strap automatically releases, the bag falls down, onto the conveyor, and the seam is completed through the conveyor and sewing machine.

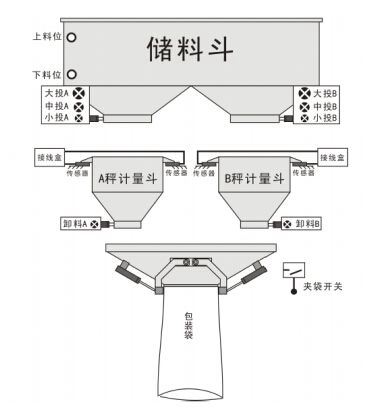

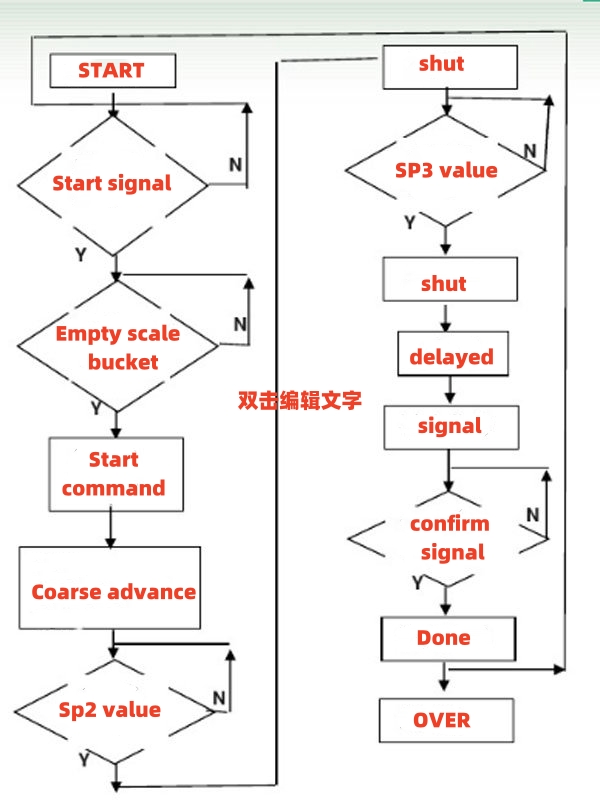

The above diagram shows the working process of weighing and feeding: press the start button of the packaging scale, and the packaging scale starts the weighing cycle. If the measuring hopper is empty at this time or the weight is extremely small and within the automatic zeroing range, the packaging scale will automatically reset to zero, and the weighing controller will send out fast, medium, and slow feeding signals. The feeding device starts to feed at full speed (fast feeding). When the weight of the material in the measuring hopper reaches the set weight point SP2, the fast feeding signal is closed, and the remaining medium and slow feeding signals continue to feed until the weight of the material in the measuring hopper reaches the set weight point SP3. The medium feeding signal is closed, and the remaining slow feeding and slow feeding signals control the slow feeding mechanism to continue feeding until the target weight is reached, and the slow feeding ends. This is the normal feeding process for three-level feeding. Some pneumatic scales are simplified to two-level feeding, which results in lower speed and accuracy compared to three-level feeding. After the slow feeding is completed, after a certain stable time, the controller makes a final judgment. If the weight value is within the tolerance range, the completion signal will be activated normally, waiting for the discharge signal. If the weight exceeds the error range, the tolerance pause indicator light will be turned on and automatically stopped, waiting for manual intervention.